Cutting, Milling, Drilling and More

RKO Plate Processing

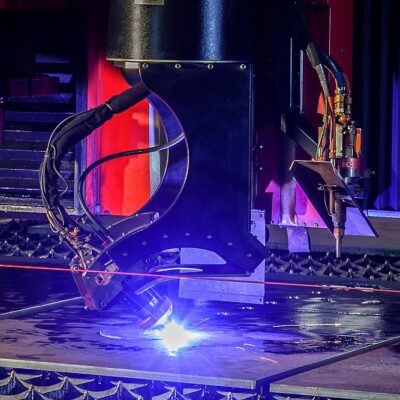

Our top-of-the-line K5200xmc is a heavy-duty combination plasma cutting, oxy-fuel cutting, and drilling/milling machine that will give your production needs a competitive edge in quality and times savings by combining processes. With multiple functions in a single machine, there’s no need for complex fixtures, multiple setups, or moving work pieces from station to station, maximizing productivity and profitability for your plate processing needs.

- Advanced Hi-Def Plasma & Oxy Fuel Cutting

- Advanced Multi-Axis Bevelling

- Advanced Drilling, Milling & More

Your one stop shop for plate processing

Specifications

---

Specifications

- Table Capacity - 10’-8” x 40’-4”

- Robotic Part Unloader

Plasma Cutting

Hypertherm HPR400XD Hi-Def Plasma Torch:

- 16GA (0.0625”) to 3” Carbon Steel

- 16GA (0.0625”) to 2-1/2” Stainless Steel

- 16GA (0.0625”) to 2-1/2” Aluminum

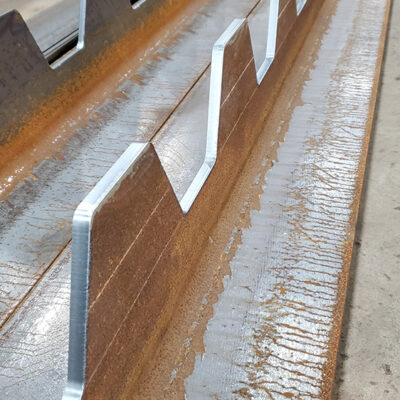

- Precision Mult-Axis Contour Bevelling

Oxyfuel Cutting

- Up to 8” Carbon Steel & Stainless

Plate Marking

- Percussion Marking

- Plasma Etching Marking & Scribing

Tooling

- 48HP Spindle & 24 Tool Magazine

- Drilling up to 4ӯ

- Tapping up to 2ӯ

- Boring, Counterboring, Countersinking, Milling and Chamfering (45° max)

- Spindle torques to 4000rpm and 860Nm (640 ft-lbs)